MAINBOT focuses on service robots that autonomously execute inspection tasks in extensive industrial plants in equipment that is arranged horizontally (using ground robots) or vertically (climbing robots).

The industrial objectives are:

- Ubiquitous sensing

- Leakage detection

- Surface and internal monitoring of equipment

Our approach is not to develop robots from scratch but to take available wheeled mobile platforms and climbing robots that have already been tested in other related scenarios as starting point, and adapt them deploying innovative solutions in order to fulfill these industrial objectives:

- Autonomous navigation: Robots (ground and climbing) must be able to autonomously navigate in a rather structured environment in a safe way

- Mobile manipulation of tools and sensing equipment for maintenance and inspection

- Sensor fusion: to exploit the information provided by multiple sensing technologies deployed in the robot

These industrial objectives will be instantiated in a real industrial scenario, a thermal solar plant that depicts common problems of this kind of plants: 230 hectares, 209.664 mirrors, 90 km of absorber tubes, huge tanks (Diam. 38 m, height 14m), hazardous working conditions.

The operation of semi-autonomous or fully autonomous mobile robots will increase the efficiency of the plant, reduce the operation and maintenance costs and improve safety and working conditions of workers.

Contribution of Fraunhofer IFF

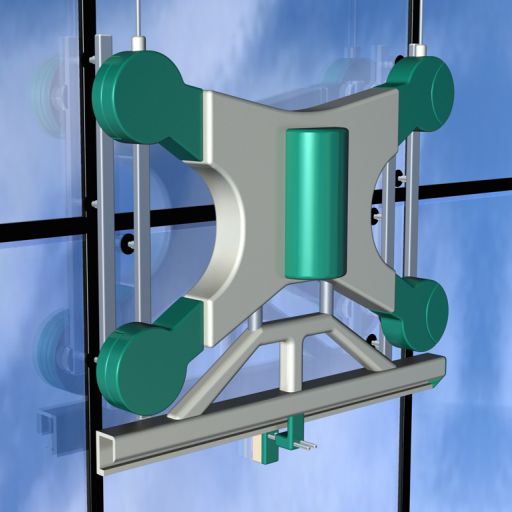

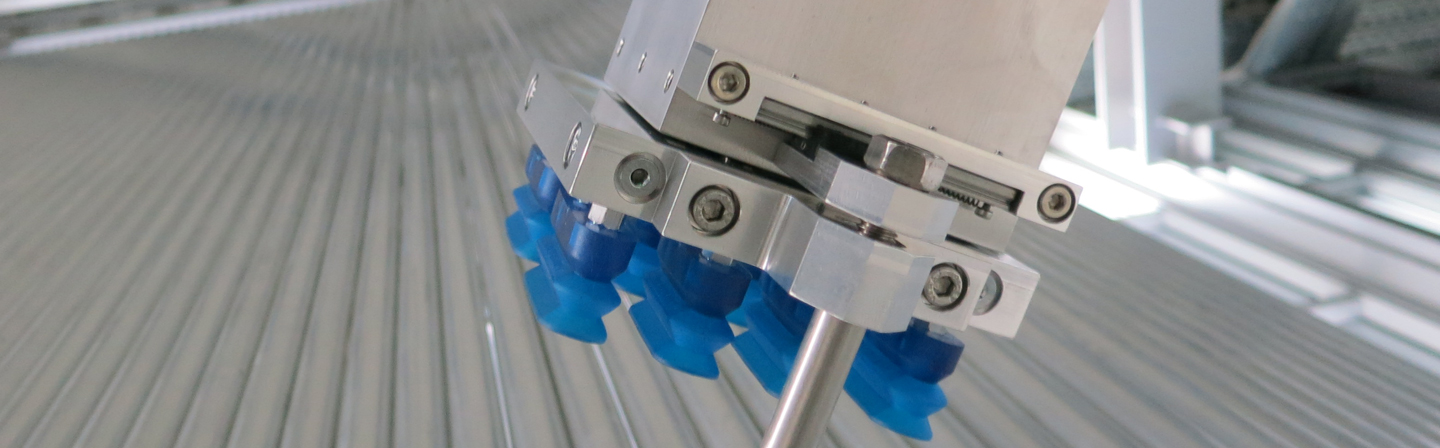

Fraunhofer IFF will develop a modular climbing robot for maintenance task on vertical structures including the automated path planning algorithm.

Consortium

- Fundación Tekniker, Eibar, Spain: Coordinator

- Robosoft S.A., Bidart, France

- Fraunhofer IFF, Magdeburg, Germany

- TECNATOM S.A., San Sebastiàn de los Reyes, Spain

- Torresol Energy Envestments S.A., Getxo, Spain