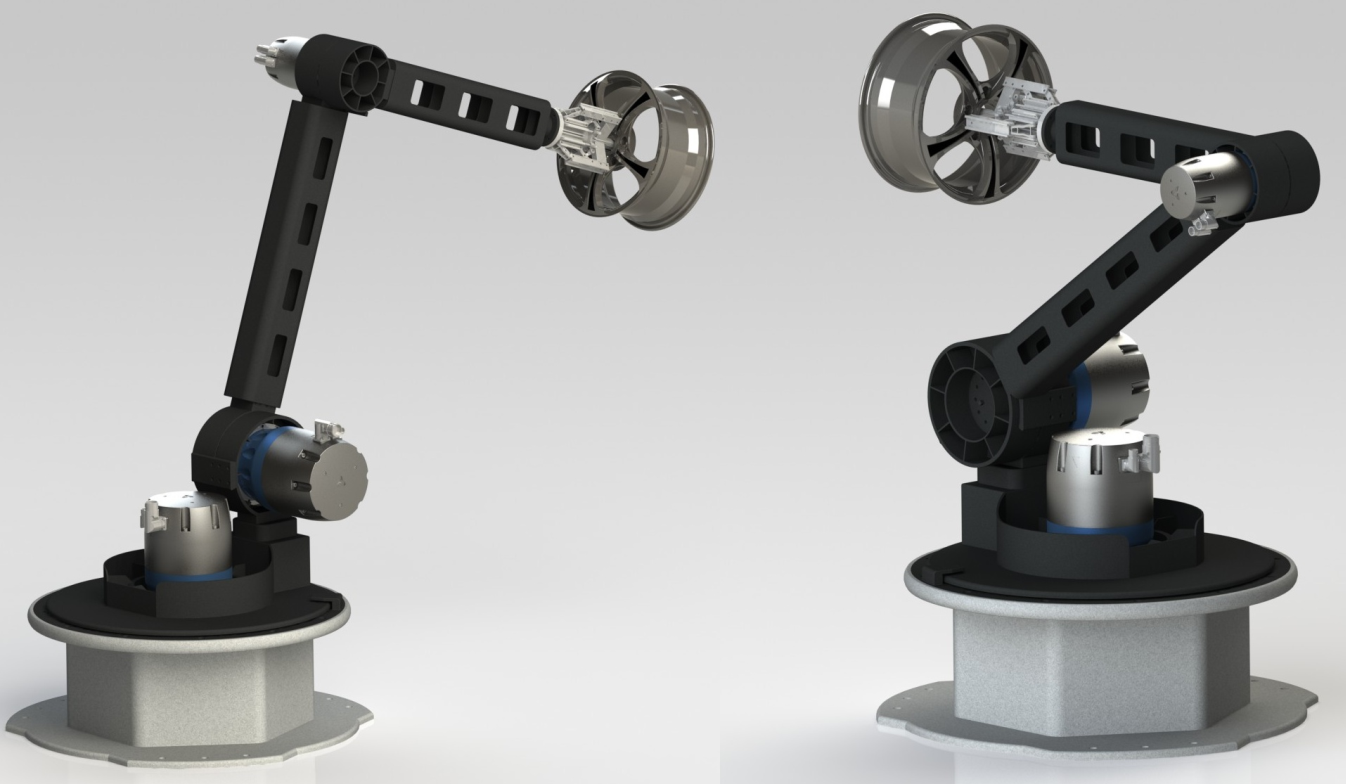

Energy Recovery from Multi-Axis Machines (ERMA)

A method for energy-saving operation of robots, machine tools and custom machines is being developed in this research project. Priority is being given to using a shared energy storage system for every drive and to smartly controlling energy flows during acceleration and deceleration. This makes it possible for part of the braking energy to be reused to simultaneously or subsequently accelerate of other drive units: The energy consumption of multi-axis manufacturing machines moving tools and lifting and transporting heavy items and so forth is largely dictated by constant acceleration and deceleration. Using energy recovery systems to save the “wasted” energy suggested itself.