We assure your product quality and process efficiency with custom system solutions

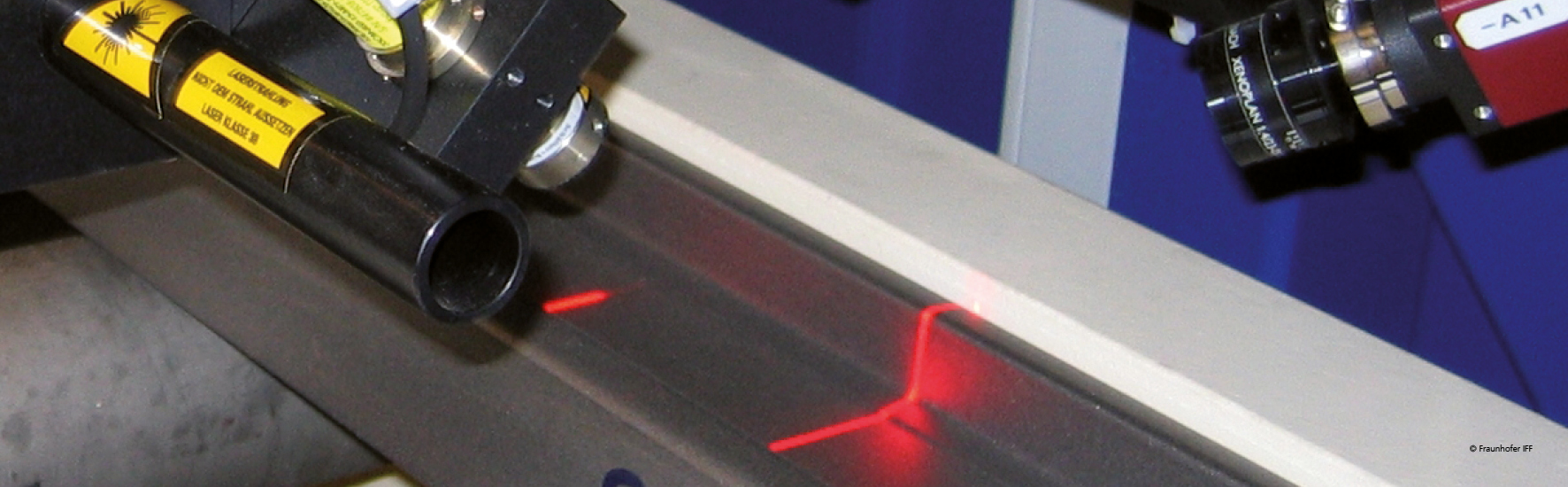

In-line scanning systems are increasingly becoming an integral part of digital manufacturing in smart factories. They detect process errors and quality defects timed and automated. They enable closed-loop quality control and thus zero-defect products and efficient manufacturing. The good automation capability and the rapid, noncontact operation of optical scanning and inspection system make them particularly attractive for use in manufacturing and integration directly in processes or machines.

We develop custom solutions for optical scanning and inspection systems. Our customers come from all manufacturing sectors. Our flexible in-line-3D scanning systems enable you to prevent product defects, eliminate time-consuming and expensive reworking and save resources. Integrated directly in a production line or machine, the technology monitors manufacturing steps and sensitive processes crucial to quality continuously and precisely timed. In this way, we help you automate and digitalize quality control processes.

Our OptoInspect3D technology tool kit is the basis for this. The technology tool kit makes it possible to implement innovative and highly flexible state-of-the-art system solutions efficiently.