Bionic Robot Arm

Bionic Arm Kinematics for Robotic Applications in Safe Human-Machine Interaction (BROMMI)

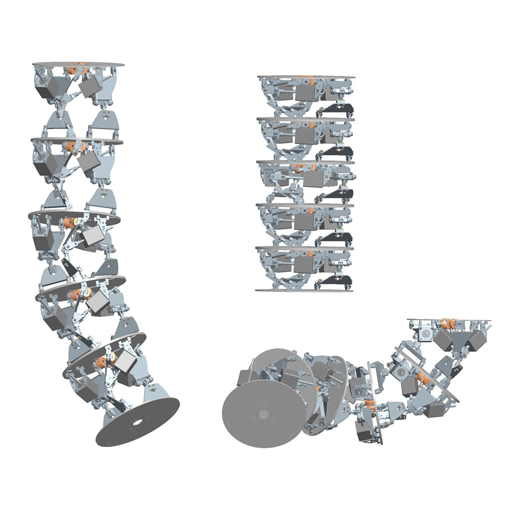

The goal of the project was the development, construction, and testing of a robotic arm that is modeled after an elephant's trunk. The robotic kinematic should be able to mimic the movements of a trunk, and, at the same time, be safe. Both are inherent characteristics of an elephant's trunk, the second one being important in the context of robot arms. Unlike conventional articulated arm robots, a trunk-like robotic arm does not have any pinching or shearing points, resulting in a lower overall risk of injuring humans. This risk is further minimized by the manipulator's typical movements, which are direct and intuitive for humans to follow and anticipate.

In the course of the BROMMI project, a new and safe robotic component was developed featuring a high degree of flexibility. It can be the basis for new fields of application in industrial manufacturing and materials logistics, where safe and direct interaction with humans is required.

Results

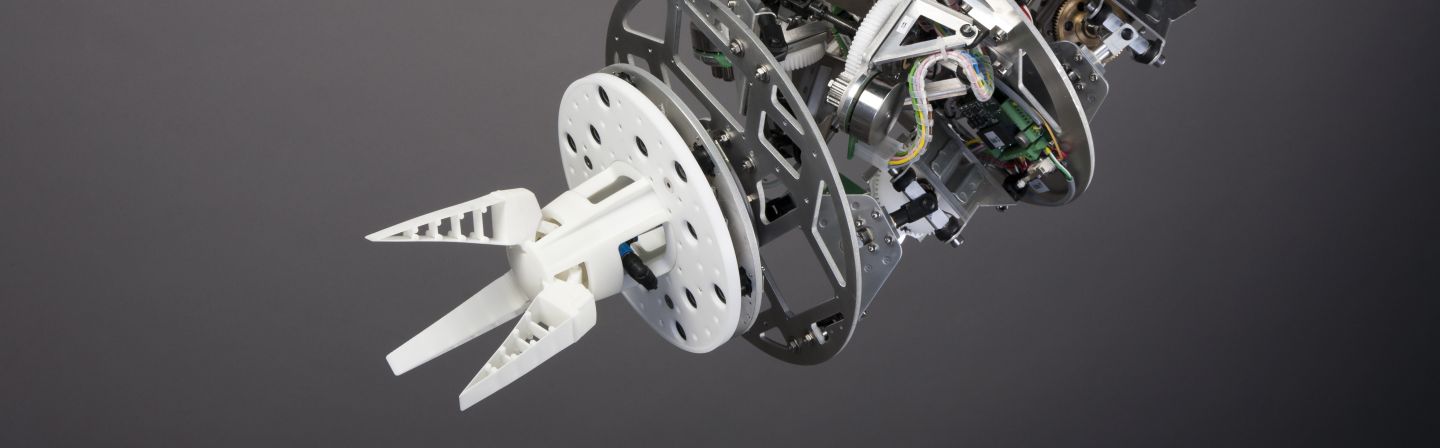

The robotic arm consists of several modules, each module having three degrees of freedom and the capability of performing both pushing and flexion movements. The BROMMI robotic arm can be shortened over its entire length and flexed like an elephant's trunk. A combination of both movements is possible as well.

A centralized controller and decentralized motor controllers are key elements of the robot control system. The master computer generates all speed and position trajectories online, and a real-time capable embedded computer assigns these trajectories to the motor controllers. In addition, an integrated image processing and differential position control system compensate position errors.

The trajectories are computed using a mathematic model of hyper-redundant kinematics. Moreover, an efficient solution of the inverse kinematic was computed.