ADIR - Next Generation Urban Mining

Automated Disassembly, Separation and Recovery of Valuable Materials from Electronic Equipment

Specific raw materials have become increasingly important to the manufacturing of high level industrial products. Electronic equipment in particular contains precious metals and a series of strategic raw materials. To date, the recycling of specific materials has focused on mass flow concepts such as shredder processes and metallurgy to extract the high-value metallic constituents such as gold, silver, and copper. However, a series of critical elements including tantalum cannot be recovered efficiently or are even lost as dust or residual fractions. The goal of ADIR is to demonstrate the feasibility of a key technology for next generation urban mining. An automated disassembly of electronic equipment will be worked out to separate and recover valuable materials.

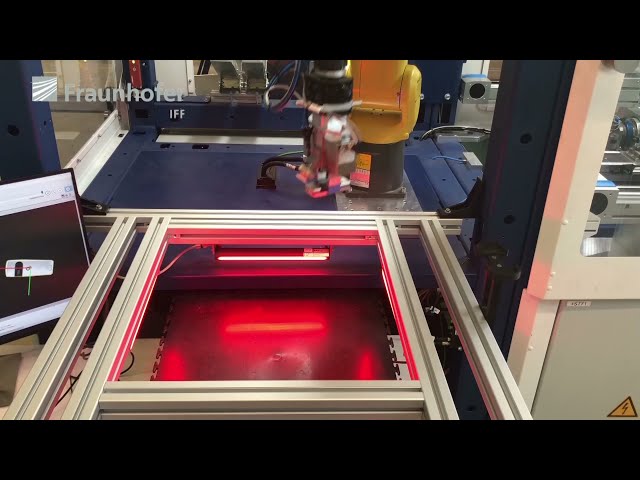

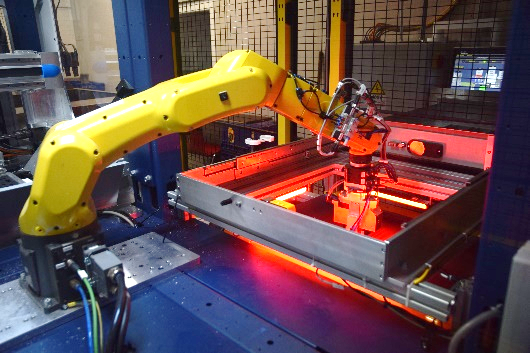

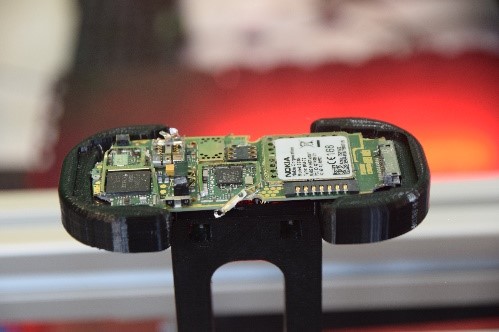

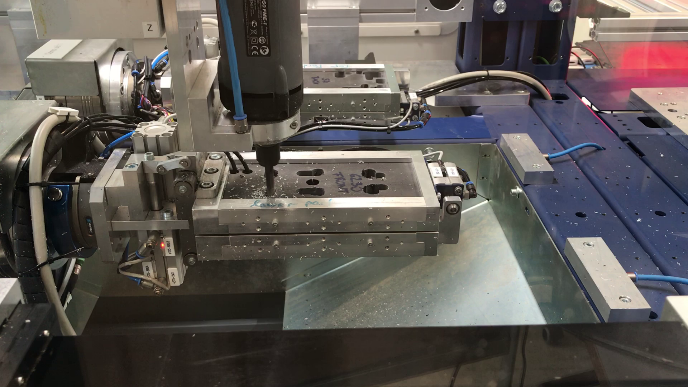

The Fraunhofer IFF joined the ADIR consortium in July 2019 and was tasked with completing and integrating the machine for mobile phone disassembly that was not finished due to a partner insolvency. The machine includes an industrial robot for handling tasks, a vision system for classifying and locating the mobile phones on the conveyor belt, and a milling station for removing the covers and PCB shielding. The complete machine works by first classifying mobile phones as they come on a conveyor belt. In a two-step process, machine learning techniques are used to identify the phone type and classify the front/back orientation and traditional image processing techniques are used for outline extraction to determine the grasping position. The industrial robot then picks the mobile phones from the conveyor belt and uses a milling portal to extract the battery, remove shielding on the printed circuit boards (PCBs), and then hand these prepared PCBs to the other machines for further processing. A particular highlight of the Fraunhofer IFF was the ability to reengineer and integrate the complete system in the short time span, and to demonstrate the role that robotics can play for sustainable production, recycling, and circular economy challenges.

The ADIR consortium uses a number of innovative techniques for extraction of strategic raw materials including pulsed power technologies for component extraction, laser processing, and metallurgical processes.

The project is coordinated by the Fraunhofer Intitute for Laser Technology ILT and the consortium consists of a range of companies including the laser specialists Laser Analytical System & Automation GmbH, the systems integrators TreTau Engineering SR and OSAI Automation Systems S.p.A, the recycling and component extraction experts including H.C. Starck GmbH, Aurubis AG, Electrocycling GmbH, and Instytut Metali Niezelaznych, and the robotics and automation specialists from the Fraunhofer IFF.

To learn more about ADIR, go visit our website