COVR - being safe around collaborative and versatile robots in shared spaces

Collaboration between robots and humans is increasingly becoming important for all sectors of the European market. Collaboration however inevitably raises safety issues, and European legislation is very careful to promote the protection of workers, elderly and weak subjects as a top priority. Market operators therefore perceive the need for “certification”, i.e. the compliance with mandatory Essential Requirements of Safety and Health, as a pressing need.

In our experience with end-users, robotics components manufacturers, and system integrators, safety has become a barrier to the promotion and availability of collaborative robotics technology in all domains. Some barriers are technical and arise to due to the complexity of robotics as reconfigurable systems that can change their behavior over time. Other barriers are non-technical and relate to understanding and correctly applying the current standards and directives to prove compliance. This is especially challenging for smaller companies.

The EU-funded project “Being safe around collaborative and versatile robots in shared spaces” (COVR) aims to systematically break down current barriers to support more widespread use of collaborative robots in a wide range of industries and domains. Our particular focus in the project is on manufacturing, logistics, agriculture, healthcare and rehabilitation.

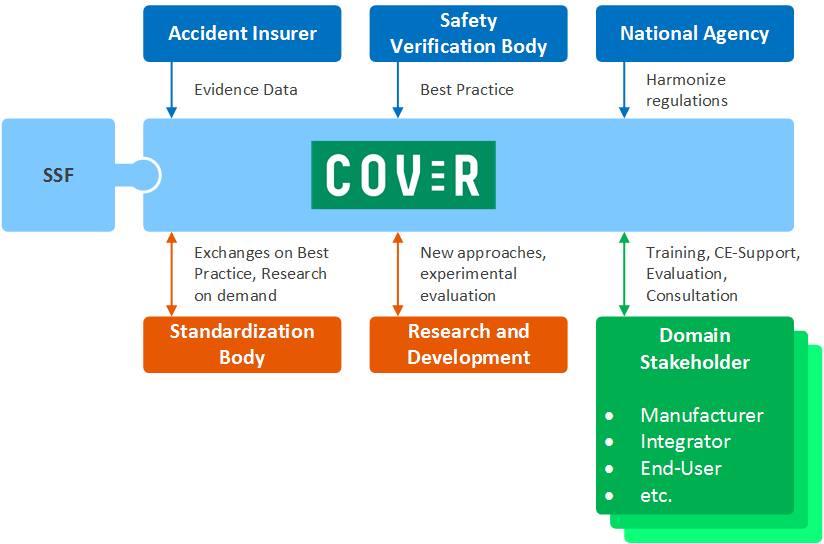

COVR offers various mechanisms for supporting the different stakeholders. First, we have developed a Toolkit as a freely available website to support all COVR stakeholders in the conception, design, implementation and validation of their collaborative robotics applications. The Toolkit builds on the concept of robot safety skills[1] – i.e. a complex combination of safety functions and protective behaviors that are valid across domains. It features a large variety of information such as case stories about cobot applications, how to find relevant standards and directives, and how to execute a risk analysis. Second, we have written over 20 protocols that are easy to follow, step-by-step guides to execute a validation measurement of applications based on their device type and safety skill involved. Third, we have updated our laboratories to become Shared Safety Facilities, where third parties can receive training, gain access to measurement systems for validation, and receive support in using the Toolkit. Finally, we have allocated over five million Euros in funding to third parties from the robotics community seeking to engage with COVR, to “stress test” the Toolkit and protocols with specific use-cases, and to provide background research and experimental data for determining best practices. We have funded 60 experiments featuring over 100 partner organizations from 14 different European countries.

COVR is driven by five Research and Technology Organizations (RTOs) – the Danish Technological Institute, the Italian National Research Council, German Fraunhofer IFF, the French Alternative Energies and Atomic Energy Commission and Roessingh Research and Development from the Netherlands. The RTOs will provide expert knowledge and assistance as well as access to test facilities in their safety laboratories.

[1] Valori, M.; Scibilia, A.; Fassi, I.; Saenz, J.; Behrens, R.; Herbster, S.; Bidard, C.; Lucet, E.; Magisson, A.; Schaake, L.; Bessler, J.; Prange-Lasonder, G.B.; Kühnrich, M.; Lassen, A.B.; Nielsen, K. Validating Safety in Human–Robot Collaboration: Standards and New Perspectives. Robotics 2021, 10, 65. https://doi.org/10.3390/robotics10020065

To learn more about COVR, go visit our website: http://safearoundrobots.com/

Twitter: COVR Projekt: https://twitter.com/covrproject , @covrproject

LinkedIn: https://www.linkedin.com/groups/8691570/