With the iDEAR project, we are solving the challenge of recovering valuable materials from electronic waste

As their lifespans grow shorter and global demand for them increases, electronics are simultaneously becoming more complex and customized. They contain a wider range of materials and the variety of products is virtually boundless. This is compounded by the many uncertainties of the disassembly of used goods. Screws can be rusted, screw heads stripped, components warped or damaged or even missing entirely. Small and compact electronic devices in particular are usually not designed for nondestructive disassembly either. Their assemblies comprise composites joined to each other by screws, levers, clips or adhesives that make them difficult to take apart.

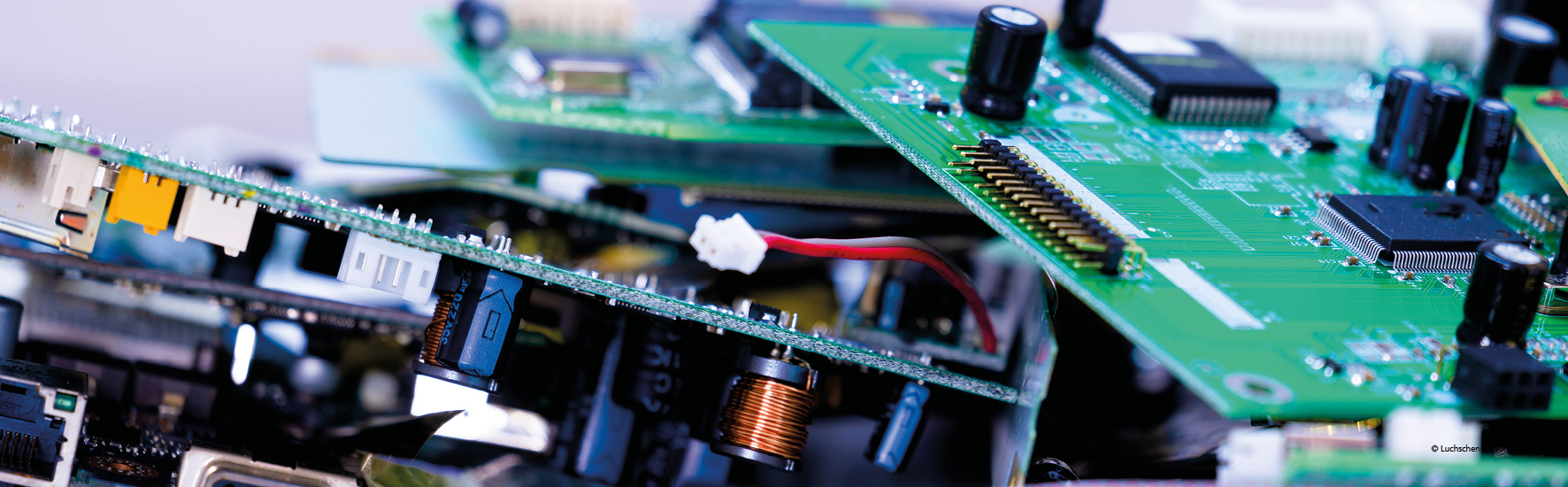

The recovery of materials from electronics is not only environmentally sound but also economically expedient. Electronic components (circuit boards, contacts, switches) contain precious metals, such as gold, silver, platinum and palladium. So-called rare earths can be found in magnets, batteries and displays. Recycling is particularly worthwhile here since, often only small amounts rare earths are available worldwide. This makes mining them difficult and the metals expensive. They are indispensable for the manufacture of many high-tech products, though. Lithium is an important part of lithium-ion batteries, which are used in many electronic devices, such as smartphones and laptops. Copper and aluminum are also frequently built into electronic devices, for instance, in cables and connectors or heat sinks and frames. In virtually every case, metals recycling always requires less energy than virgin raw material mining and processing.

The recovery of all these materials consequently not only reduces the environmental impact of electronic waste but also of raw material mining and constitutes a valuable source of raw materials for new products.

The better the individual materials are separated from each other during disassembly, the better they can be reused as secondary raw materials and the less energy is required for any particular recycling process. The very few specialized systems currently able to disassemble a very limited number of products automatically require substantial engineering.

In the iDEAR project, we are developing solutions for the intelligent disassembly of electronics for remanufacturing and recycling. We are developing processes for orderly, formal recycling using advanced automation technologies with which valuable materials can be recovered and reused efficiently, making the future of the electronics industry more sustainable.