Transparency as the Basis for Intelligent Decisions

Digitalization in manufacturing is offering new opportunities to design processes, machines and products. Fully utilizing and expediently combining all options with each other produces the industrial ecosystem envisioned by Industrie 4.0, featuring extensive interconnectivity and dense information flows. Data are exchanged horizontally along the supply chain beyond the confines of the company and vertically within a production system, from components to machine controllers down to management. Digital components initially concealed from human perception constitute a crucial challenge when operating such cyber-physical production systems. Unlike the conventional machines and standard factories of recent decades, increased use of sensor systems is generating significantly more data that are collected, stored and transmitted digitally. Machines and products that communicate autonomously with control systems that plan and control production are superseding people as custodians and transmitters of information and increasingly assuming the role of decision-maker and inspectors.

How can we help you transition to an efficient but transparent and thus controllable production system?

- We develop custom tools and designs for your business, which visualize information flows and elucidate causal relationships.

- We offer workshops and management games, which illustrate the ideas of digitalization understandably and practically.

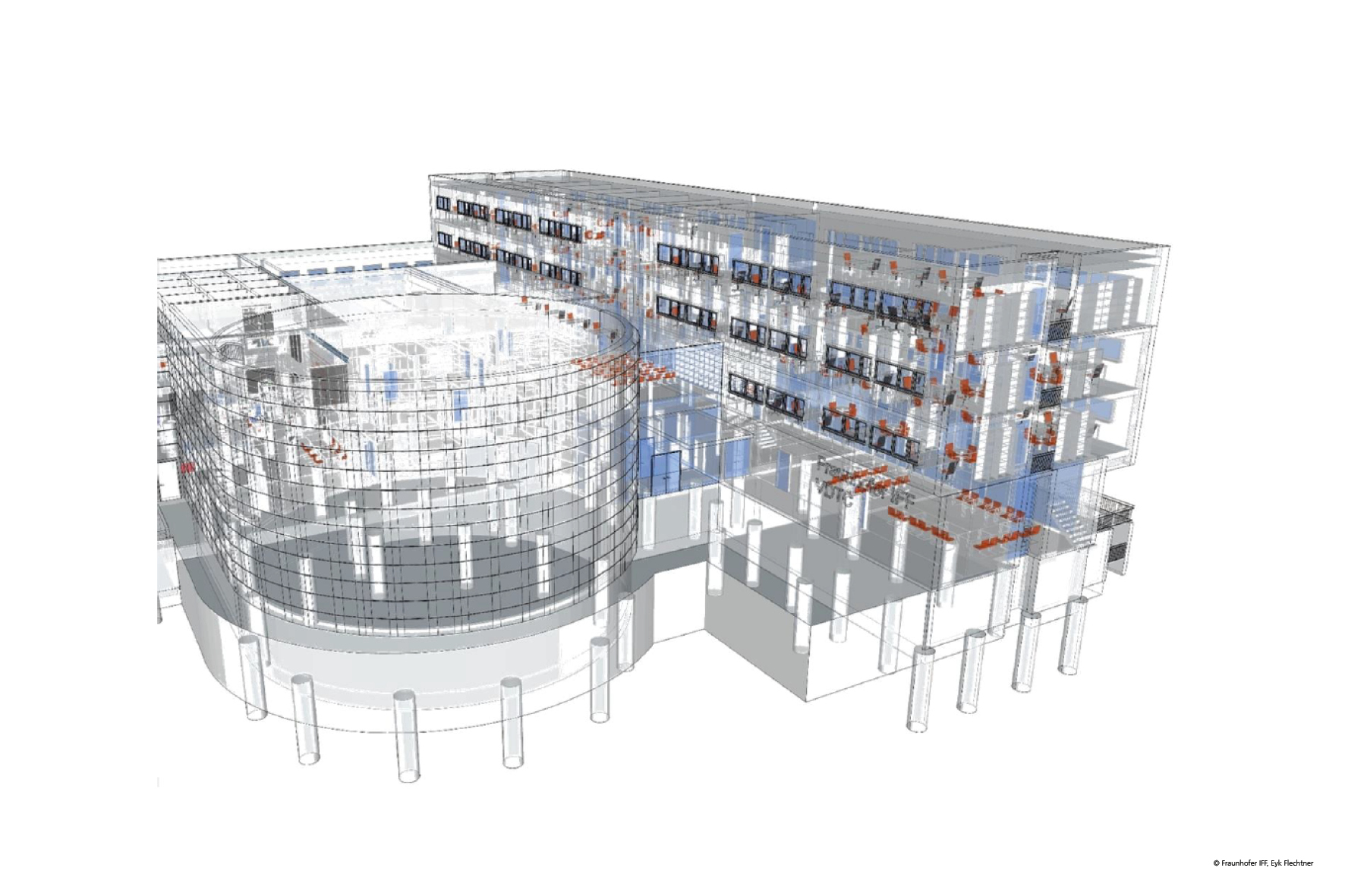

- Using our wide range of technologies, tools and methods, we enable you to create a digital factory map of your production system.

Our mission is thus to develop and employ tools and designs that visualize information flows and elucidate reciprocal relationships. For us, a transparent factory is a place where people can look inside machines, products, processes and digital communication and identify causal relationships quickly and precisely without opening any enclosures, without having to be on site, and without expending time and labor to analyze data. Only then can fast and expedient decisions be made.