Designing Resource-Efficient Processes’ Value Streams

Are you wondering where waste occurs in your business processes? Lengthy lead times, supply problems, large inventories and long waits are but a few of the potential deficits in the material stream. We rely on value stream mapping as a suitable method for boosting efficiency in your business. It is essential to define performance indicators that measure productivity. Manufacturing and logistics processes can be correspondingly visualized, especially when complexity in manufacturing is high.

What theoretical and practical contents are imparted?

- basics of digital transformation and lean principles,

- introduction to the value stream method, and

- group work and discussions reinforcing the material taught.

Your concrete benefits:

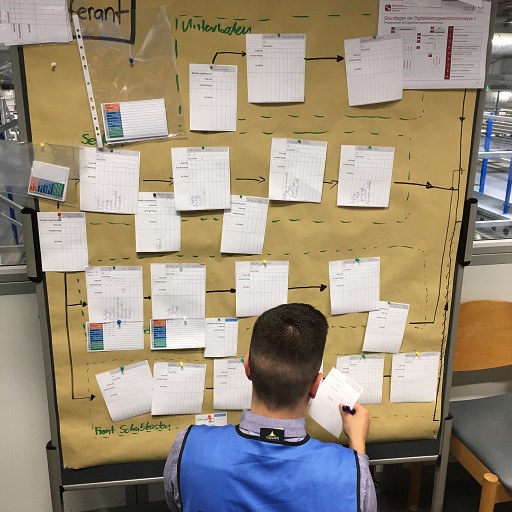

- a workshop on value stream design to identify waste in material and information flows,

- value stream mapping as a catalyst to increase internal value creation,

- improvement of process control in manufacturing and logistics,

- illustration of the as-is state to infer optimization capabilities, and

- sustainable improvement of “manufacturing efficiency”.

Pinpoint information losses with the digitalization value stream

Value stream mapping enables you to map the as-is state of all material stream and information processes, yet detailed analysis of information logistics processes, e.g. format changes, remains overlooked. The digitalization value stream adds digitalization factors to the conventional value stream method. We also present concrete implementation options with some examples from our digitalization lab.

What questions are answered during the seminar?

- What is digitalization value stream mapping and why are pencil and paper used for it?

- How does digitalization value stream mapping work?

- What are the types of digital waste?

- How does digitalization value stream mapping help detect digital waste?

We will help you detect format changes, transmission errors, duplicated work or even unanalyzed information. In the end, you will be able to detect digital waste and develop ideas for improvements on your own.